Why a 99% MRP Service Level Is Not Enough in Aerospace MRO

In aerospace maintenance, logistics performance is often assessed using reassuring indicators such as the MRP service level by part number. Many MRO facilities therefore report availability rates above 99% across most of their inventory. Yet despite these seemingly excellent figures, delays continue to build up, engines remain immobilized in the shop, and Aircraft On Ground (AOG) situations keep increasing.

This gap between measured performance and real operational performance is neither temporary nor the result of poor execution. It stems from a structural bias in the way inventory is managed. MRP operates at the individual part level, whereas aerospace MRO requires the simultaneous availability of a complete set of components to ensure an engine can actually be repaired.

The Industrial Reality of Aircraft Engine Repair

Aircraft engine repair bears little resemblance to a serial production process. Each engine is a complex system, exposed to different operating conditions, whose true condition is only known after teardown and inspection. A standard overhaul may require dozens, or even more than one hundred different components, distributed across multiple disassembly levels.

Some parts are systematically replaced, while others are changed only when defects are detected, making the actual repair bill of materials highly uncertain before the engine enters the shop. This uncertainty is further amplified by the diversity of part families, ranging from certified critical components to technical consumables, each with its own supply constraints, cost structure, and lead times.

In this context, engine repair depends on a strict sequence of operations. As long as a single required part is unavailable, the entire process comes to a halt. Teams, test cells, and industrial capacities remain engaged without creating value, while the engine accumulates in work-in-progress.

This logic of total dependency on the most constrained component lies at the very heart of material shortage issues in aerospace MRO.

How MRP Works — and Its Fundamental Bias in Aerospace MRO

MRP was designed to plan component requirements in environments where bills of materials are stable and demand is relatively predictable. In aerospace MRO, it is used to size inventory for each part number individually, with target service levels typically ranging between 95% and 99%.

Safety stock calculations are based on historical consumption, average forecasts, and assumptions about variability. This approach works reasonably well when an occasional stockout of a single item has only a limited impact on overall production.

In aircraft maintenance, this assumption does not hold. A shortage, even a rare one, is never local: it immediately blocks the entire repair.

Yet MRP continues to optimize each part independently, without considering the fact that components are consumed jointly. The system therefore reaches a local optimum, where each item is correctly sized in isolation, while the overall performance of the repair process deteriorates significantly.

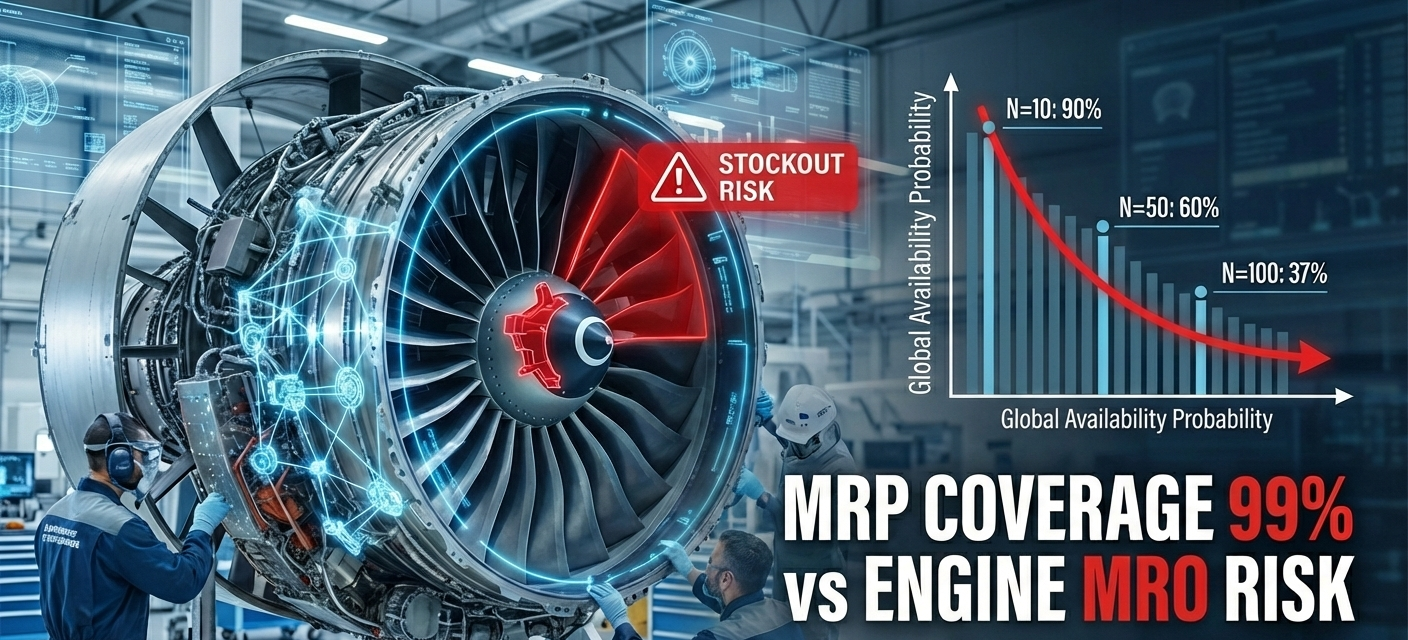

The Multiplicative Effect of Multi-Component Repairs: A Simple Demonstration

The core of the problem can be explained through a simple probabilistic model that is particularly intuitive for industrial organizations. If a given part has a 99% probability of being available when needed, it is missing in 1% of cases. When a repair requires only one part, this risk is low. But when it requires a large number of different parts, the probability that all of them are simultaneously available becomes the product of the individual probabilities.

Mathematically, if a repair requires N different components, each with a 99% availability probability, the probability that the repair can proceed without any shortage is equal to 0.99 raised to the power of N.

With ten components, this probability remains close to 90%. With fifty components, it drops to just over 60%. With one hundred components, it falls to approximately 36%.

36% Coverage Rate

In other words, in an aircraft engine MRO shop where a repair involves around one hundred parts, two engines out of three are statistically exposed to a supply chain blockage—even with an excellent service level per item.

Why the Issue Is Even More Critical in Engine MRO

This theoretical risk is amplified by several realities specific to aircraft engine MRO. First, part requirements are not fully known at the beginning of the repair. They emerge progressively during teardown and inspection, which means shortages often occur late in the process, when the engine is already deeply engaged in the industrial flow.

Second, lead times for critical parts are often very long—sometimes several months—due to certification constraints, single-source suppliers, or limited industrial capacities. A shortage therefore cannot be quickly offset by an emergency order.

Finally, the industrial cost of these shortages is highly disproportionate. An engine immobilized in the shop delays the return to service of the corresponding aircraft, generating extremely high AOG costs for airlines, in addition to contractual penalties, internal costs, and degradation of customer relationships. In this context, the incremental cost of higher safety stock is often marginal compared to the true cost of a shortage.

The Most Common Inventory Management Mistake in MRO Organizations

Many MRO organizations continue to manage supply performance using indicators inherited from serial production, such as MRP service level by part number or total inventory value. These indicators provide a reassuring but incomplete view of operational reality. They do not measure the number of repairs blocked by shortages, the cumulative time engines remain immobilized waiting for parts, or the direct impact on customer lead times.

By focusing on local item-level performance, companies miss what truly matters: the ability to complete an engine repair without supply interruption. This confusion between local performance and global performance is one of the main reasons shortages persist in engine MRO.

From Inventory Logic to Repairability Logic

The most mature MRO organizations have gradually shifted their paradigm. They no longer aim solely to optimize inventory part by part, but to secure the overall repairability of the engine. This means reasoning in coherent sets of components associated with repair types or engine families, ensuring that critical parts are simultaneously available when the engine enters the shop.

This approach also leads to a redefinition of part segmentation—not only based on financial value, but on industrial criticality. A low-cost but blocking part must be managed with the same level of attention as a very expensive component.

Similarly, the implementation of strategic buffer stocks at key points in the supply chain helps absorb the real variability of MRO demand and protect engine turnaround time.

Optimization and Mitigation Levers

-

ABC Segmentation: classify parts by criticality and volume (e.g. ABC/XYZ classification). “A” parts (high cost or safety-critical) are managed with very conservative MRP parameters (higher safety stock, stricter service levels), while less critical parts can tolerate lower coverage. This focuses resources on components that most impact overall availability.

-

Strategic Buffers (DDMRP): place buffer stocks at key decoupling points (DDMRP patterns). For example, decoupling the flow of critical parts with a controlled stock point helps absorb demand and lead-time variability. DDMRP’s principle of “decoupling to protect flow” directly mitigates the multiplicative effect described above.

-

Kitting Policy: prepare complete part kits in advance for each type of intervention. In other words, group all required parts (and sometimes spares) into a single order or package. This widely used maintenance practice ensures no essential part is missing and accelerates technician work, while improving inventory control.

-

Adaptive Inventory Management: increase safety stock for critical parts, diversify suppliers or consignment stocks, and dynamically adjust MRP parameters based on real demand variability. Parts with very long lead times or frequent failure histories should be assigned additional buffers. Although more inventory-intensive, these measures significantly reduce the risk of global shortages.

Rethinking Inventory Management in Aerospace MRO

The key message for industrial leaders is clear: in aerospace MRO, a 99% MRP service level per part does not guarantee on-time engine delivery.

The more components a repair requires, the more the risk of global shortage increases exponentially. As long as inventory is managed with a local, part-centric logic, MRO shops will continue to face costly and hard-to-explain blockages.

The only sustainable response is to adopt a systemic, engine-repairability-oriented vision that integrates multi-component complexity, demand uncertainty, and the true cost of shortages.

In an environment where engines are becoming increasingly complex and supply chains more fragile, this shift is no longer a competitive advantage—it is an industrial necessity.

Deploying Operational Management Tools

In the context of aerospace MRO, it is now widely acknowledged that supply chain disruptions are no longer exceptional events but a structural reality. Supplier delays, quality issues, raw material shortages, certification constraints, geopolitical tensions, or sudden changes in shop load are part of daily operations in engine maintenance organizations.

In such conditions, traditional planning methods—even when well configured—quickly show their limits, as they are designed for stable and predictable environments.

The ability to react quickly therefore becomes a key factor of industrial performance. This requires tools capable of immediately visualizing the impact of a shortage or delay on engines in progress, identifying truly critical parts from a repairability perspective, and enabling fast operational trade-offs between priorities, inventory, and resources. This is precisely the logic behind Robin by Zozio, which provides a real-time, systemic view of the MRO shop and its supply chain.

By focusing on engines, operations, and tangible risks rather than theoretical indicators, this type of solution enables industrial teams to turn unavoidable disruptions into controlled decisions—reducing reaction time and minimizing the real impact on return-to-service lead times.