[ Interview 4.0 ] Harness the power of the digital twin to model an industrial environment

A digital twin is a virtual replica of a physical object. In most cases, digital twins used in industrial environments are innovation tools dedicated to process simulation and/or performance analysis.

To talk about what makes Zozio’s digital twin so special compared to other tools on the market, we interviewed Walter Gabriel, our CTO (Chief Technical Officer).

Zozio: Walter, can you tell us more about the usefulness of the digital twin?

Walter: In general, when we talk about a digital twin, we’re talking about a tool that’s far removed from the value chain, which can be used to simulate environments, predict behavior and avoid errors in the design of a product or even a factory. This type of simulation can be used as a basis for reflection and decision support for a number of use cases:

- Considering the positioning of a machine,

- Optimizing production or logistics flows,

- Optimizing the behavior of collaborative robots and their movements in the physical world,

- Analyze any type of situation and simulate the associated risks.

When the plant emerges from the ground 4 years later and starts production two years after that, its final design will have been informed by the cross-referencing of the various hypotheses generated by the simulation, and the best options will have been selected.

Zozio: And the more specific use of the digital twin developed by Zozio?

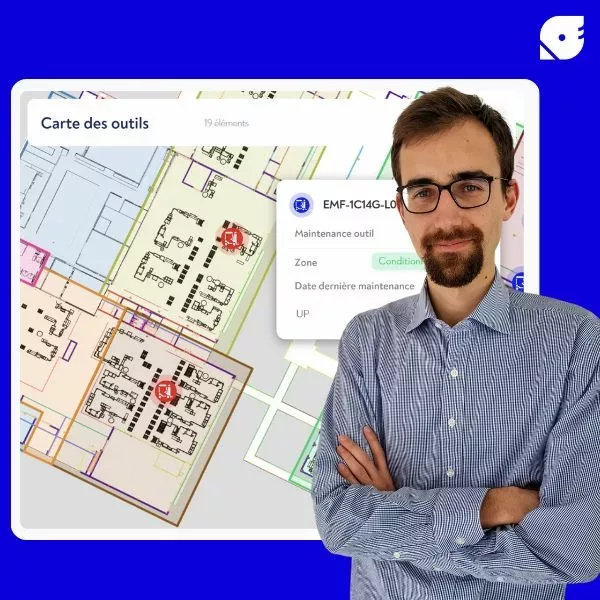

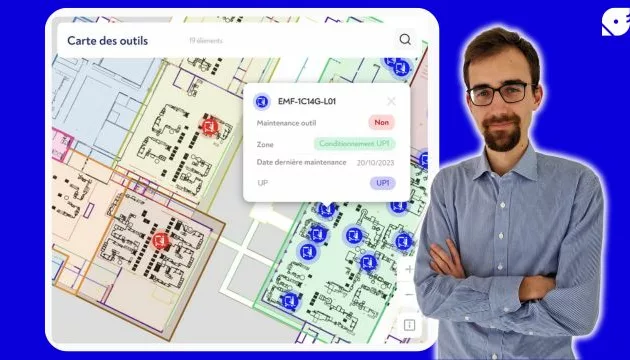

Walter: At Zozio, it’s not a simulation that we offer, but a model of the physical space combined with real-time flow data. We model production tools, containers, work-in-progress and the factory itself, in order to obtain a digital replica, accessible in the cloud and providing access to key data that can be shared by all.

With the type of digital twin we are developing, our customers have access to information in digital format to manage traceability and collaboration (information sharing) in real time from a “single source of truth”. Our tool is designed to centralize and distribute information to the right place. This grouping contributes to improved ergonomics and the creation of additional data.

Zozio: Who is the target audience for this kind of tool?

Walter: It’s more likely to be operators and managers in the field, production experts who will need this type of information. In the cosmetics industry, for example, they’ll be tracking the status of tanks (washed, disinfected, empty, full, etc.) or containers with the juices stored in them, looking for their position inside the plant, but also at subcontractors’ sites. They want to know which containers are available and how many are immobilized, and any other maintenance, certification or quality status…

Zozio: Which KPIs are you most interested in?

Walter: We can provide many types of KPI based on data such as statuses, which enable us to generate utilization rates or average durations per stage. It’s easy to set up fields on our platform, and we work as if on an Excel spreadsheet. We are able to work with a wide variety of fields from different sources, such as :

– fields extracted from ERP,

– fields from manual records such as events (maintenance, quality, subcontractor visits) and problem records (blockages, late deliveries, etc.),

– fields relating to geolocation data (production zones or industrial sites),

– fields resulting from automatic rules we have configured to model a business or logistics process.

Zozio: What’s the advantage of using ROBIN, our software, rather than an ERP or MES?

Walter: Our software can absorb data from these programs if they already exist in the plant’s information system (IS), and from this data we can provide more accurate, real-time information, combined with geolocation data.

Usually, the person configuring the data tables in the ERP is a specialist (consultant, developer, IT specialist). What makes our ROBIN platform different from an ERP or MES is that we can train people to be autonomous in these areas, without them having to be specialists. Our customers appreciate the speed of “no-code” parameterization – which means no technical requirements – but above all, no need to call on an additional service.

It’s the ergonomics of this no-code system that enable us to handle the modeling of assets and the updating of asset properties at the same time, thanks to automatic rules and/or forms. The configuration of visualization interfaces or widgets (inventory tables, maps, graphs and indicators) provides an overview of the information generated in just a few clicks.

With software such as Apriso, to name but one, it would have been necessary to generate several data table exports in order to obtain this information and optimize production. None of this would have been automated.

Zozio: What do customers need to supply when setting up the digital twin of their WIP?

Walter: If we’re monitoring production tools, we need an Excel table to initialize the list of assets. To set up real-time data feedback, we interconnect the ERP and our ROBIN platform to collect the status of asset values and fields, or to retrieve new OFs.

If there’s an IoT deployment to be planned, we draw up a specification that includes a fixed infrastructure with anchors, a gateway and mobile tags, all without cabling. The installation can be carried out by the customer if they wish, as our geolocation technologies are very easy to deploy.

Then, with the customer, we organize a few key points around the project to find out which fields need to be retrieved and which need to be added. The platform is then configured after modeling the assets and considering the different interfaces required by operators and managers.

The customer also provides us with a map of his industrial site – recent and to scale. From this map, he can visualize the location of his assets and their movements in real time, as well as all the fields and attributes predefined together. He can also use the system of filters and views to switch from a global map to one dedicated to maintenance operations, for example.

Zozio: What is the perceived value of the digital twin to the customer?

Walter: Our customers appreciate the fact that we give them access to information in a few clicks and in a variety of formats. Often, the problem is not the lack of this information, but its accessibility in the field. Operators don’t have the time, and don’t always know how to make an SAP query to obtain information. So we give them access to this data and supplement it with geolocation to save them search time (on average 30 minutes per day per operator).

Our aim is to adapt to our customers’ processes, and to be responsive to any changes that may be required, such as the type of asset (tank, container, IBC, forklift, etc.) to be tracked. New objects are not supported on SAP. On our ROBIN platform, we are not constrained and can create any new type of object to track very easily.

What we offer is an automated control tool that eliminates time-consuming routines and improves the quality and working conditions of production experts in the field.

An interview with Walter Gabriel, CTO Zozio.