At the verge of the 3rd Industrial Revolution, the Lean Manufacturing cut a path through better production performances. Recently, as the plants’ complexity is growing and whilst the supply chain is under pressure, the Industry 4.0 is bringing some innovations on the table to adress the new challenges of the industry. The Just-in-Time Manufacturing method is one of it and leads to one of the most promizing answer for the field, supported with a powerful software solution.

MES and Lean Manufacturing limitations

Invented at the very heart of the Toyota factories in Japan, after the WW II, Lean Manufacturing has proved its worth particularly in linear assembly production environments with little versatility, high levels of mechanization and low dependence on human resources – such as the automotive sector.

This method has proved its worth in a given context, and – more generally – industry has benefited from the teachings of Lean Manufacturing to reorganize its processes and pace its production. However, since the3rd Industrial Revolution, society has been transformed and the foundations have been disrupted by new uses.

New industry challenges call for transformation

The hyper-industrialization of products and the advent of a more service-oriented society have led to a shift in demand from BtoC and BtoB segments. This has had an impact on subcontracted supplies and added another layer of complexity. The globalization of the supply chain and its unreliability have made industrial players with long supply chains particularly vulnerable.

To remedy this, they have one solution at stake, which is to try the resilience of their supply chain and seek to anticipate and make transparent the sources of risk (at suppliers of all ranks, in production, distribution…).

Variability of operations: a source of mental workload

This variability of operations also has an impact on production. Expanding product ranges creates more complex production processes that are less amenable to automation. As a result, production flows are more erratic. Production costs and lead times are higher, and the growing complexity of the product undermines First Time Capability (FTC). Uncertainty as to whether resources will be received correctly is leading to a rise in inventories, both at the factory gate and in the semi-finished areas. Intrinsically, this forces operational staff to be more vigilant about scheduling management and frequency (short-term planning), and to be more reactive in the face of unforeseen events.

In industries where production is organized into workshops (Job Shop Manufacturing) with so-called “spaghetti” flows, where operators and logisticians interweave in a series of both manual and machine-assisted operations, it becomes more complex to foresee and anticipate risks, optimize production rates and organize good collaboration between staff.

MES out of touch with reality in the field

One might think that pre-existing software would be sufficient to manage this complexity. However, business software such as MES (Manufacturing Executing System) plays an essentially administrative role. They only have a link with the field when it comes to declarations made manually by operational staff. When an employee omits to enter information, this can generate an inventory discrepancy.

When WIP is moved from station to station, stored and checked, there is still a risk that these steps are not taken into account. This makes it difficult for a scheduler to know the real state of production, and for an operator to find his WIP.

Gaps in field collaboration

Nowadays, teams tend to work in silos and collaborate only at shop floor level. This creates a tendency to look only at one’s perimeter, and not at the whole of production. What’s more, operational staff who optimize their production KPIs tend to overproduce, and fail to produce what is useful for the next stage after their own.

Few systems are able to tell operational staff what the most optimal task will be, and what’s more, in real time. In the vast majority of cases, the operator will take the first OF that comes along, or the OF with the highest priority delivery date.

Impact on scheduling and production

To optimize production, continuous attention is required. This leaves two possibilities:

– Either a person is in charge of checking and correcting production errors at every moment (which is virtually impossible),

– Or an automated system can measure the actual situation and propose corrections.

Servo-control: a method for managing fluctuations in real time

An analogy can be made with the temperature of an oven. The cook programs the thermostat to give the oven its set temperature. As this temperature fluctuates, the oven will measure its internal temperature to adjust its heating power. This is known as servo-control.

The system is far more complex in the case of production, particularly in so-called Job Shop Manufacturing. The first reason is that there are numerous resource constraints: stocks, tools, machine capacity, human availability, etc… A thorough load-capacity analysis must be carried out for each schedule. Then there’s the customer delivery date and delays, which must be minimized as far as possible. The scheduler must also limit WIP buffer stocks, which are used to absorb production contingencies.

Since production orders tend to be scheduled on a first-come, first-served basis, and this is rarely the most efficient method, in order to improve, the scheduler should theoretically seek to minimize production delays overall, rather than aiming to absolutely deliver the product to the highest-priority customer. Because, in this configuration, all customers are unhappy because… they’re all late!

It’s therefore almost impossible for the scheduler to find the ideal solution with all these cross-instructions. Managers will tend to overproduce and create large buffer stocks to counteract these risks. Production is then carried out on a “push” basis, and continues even though the need has not yet been established. The result is reduced productivity and non-quality.

Solving industry challenges with just-in-time scheduling

Faced with the sum of these new challenges, manufacturers are looking for solutions to increase the predictability of operations and improve the management of complexity.

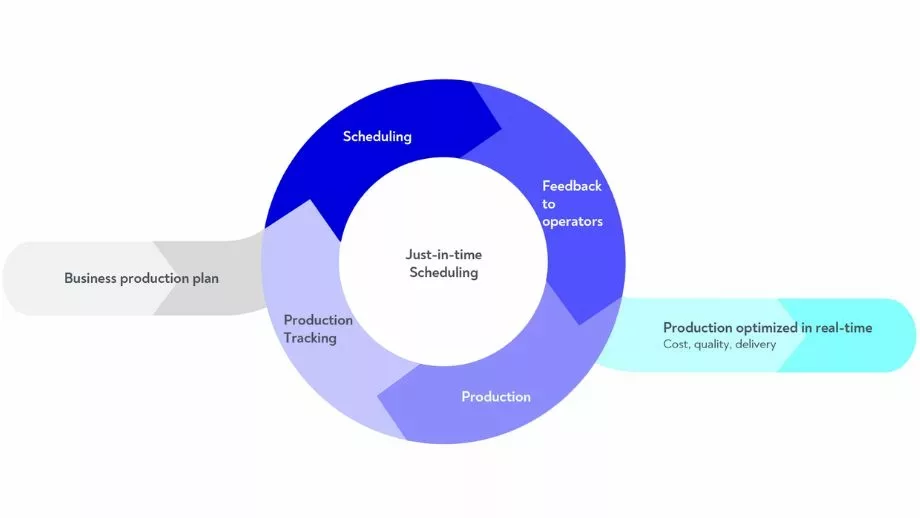

With just-in-time production, the flagship objective of Lean Manufacturing, operations can be optimized thanks to real-time measurements – measurements which enable us to visualize when production is drifting away from the initial order (generally called PDP or Production Plan).

To obtain these real-time measurements, performance management software is deployed within the plant or on moving containers and equipment to interconnect business data and bring them together at a central point, combined with an IIoT solution (industrial sensors) to track products, containers and handling equipment.

With this centralization, the data collected can be activated. IT and physical flows are harmonized, and production scheduling is supported by a global rather than a local vision, guaranteeing very high performance.

Guarantee the cost – quality – deadline triptych

The solution is based on production servo-control. The long-term average production plan acts as a setpoint for production, like the temperature for the oven. This setpoint is derived from customer demand. The supply chain teams provide a sales forecast, and the three parameters to be optimized are cost – quality – lead time.

To check that these commitments are respected, production must be measured at all times. Geolocation enables us to monitor production and stock levels in real time. It measures deviations from production planning and scheduling.

Once a deviation has been detected, the real-time scheduling tool must be able to alert you to the deviation and, where possible, propose an alternative so that other workstations do not suffer delays.

The effects of Just-in-Time on human capital

Better management of complexity creates a more favorable working environment for production professionals. We break the operator’s isolation by involving him in the production chain, thanks to access to real-time information and a global vision. Better informed, they can get to the heart of the matter more quickly and concentrate on their core business.

The automation of low value-added tasks – such as certain types of routine – frees him from an unnecessary and avoidable mental burden.

In conclusion, Just-in-Time Manufacturing represents a significant step forward in the transformation of production methods. This approach, based on factual data and in-depth analysis, offers a tangible solution for overcoming today’s manufacturing challenges. By integrating this innovative approach, companies can not only remain competitive, but also improve their agility, quality and profitability.

An article by Bastien Triclot

Founder and CEO of Zozio