Model your current and future production constraints: replenishment, resource transformation, available teams, parts stocks, available tools and containers, machine status and maintenance cycles.

Better scheduling with ROBIN Daily Scheduling

Plan your production in real time

ROBIN Daily Scheduling is a real-time production scheduling module integrated into our ROBIN software.

This module is specifically designed for industrial manufacturers, performance, continuous improvement and operational excellence managers, as well as any field expert responsible for optimizing plant flows.

Thanks to the ROBIN API, our solution integrates seamlessly with your existing information systems.

Thanks to its intuitive interface, you can :

– Improve visibility and coordination of your production operations,

– Adjust your planning in real time,

– React quickly to demand fluctuations or supply chain disruptions,

– Improve inter-team collaboration,

– Review data collected in the field to identify optimization opportunities.

Analysis of your load-capacity

With ROBIN Daily Scheduling, you’ll have a clear picture of your load-capacity, updated in real time.

Identify at a glance your limiting resources (available personnel, machine operation, raw materials, available containers, etc.) to achieve your production targets.

Model your constraints for better scheduling

Based on this modeling performed on our software, get precise views of potential failures so you can anticipate them and re-schedule accordingly.

Pull flow planning

Pull planning takes into account your entire production flow. This has the effect of keeping production in all workshops at the same rhythm, limiting buffer stocks and thus reducing overall lead time.

Track your production steps in real time

Need to track your production as closely as possible?

Call on our experts to draw up a set of specifications tailored to your use case, integrating smart tracking technologies (IoT) to track your assets in real time and deduce the stages of production in progress, so you can anticipate and correct the risks of delays.

Have you heard of ESLs (electronic tags)? With these connected objects, get your re-planning instructions down quickly to operators and managers in the field.

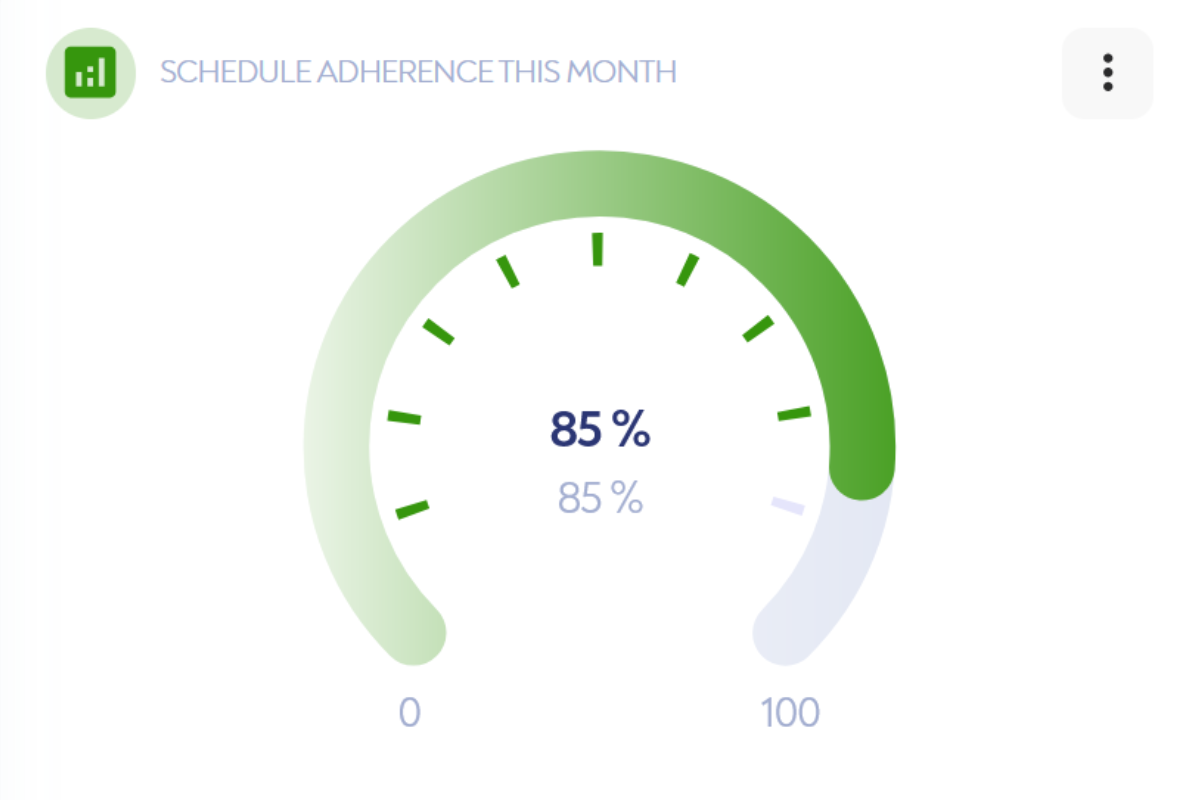

Measure your adherence to scheduling

Make sure you’re following your production schedule, and measure your adherence to it. This will enable you to implement continuous improvement actions.

Collaborate better with your teams

Share information easily with your teams thanks to a verified, reliable and accurate data source for better inter-team collaboration.

Discover ROBIN Digital Twin