What is the Gemba Walk?

The Gemba Walk is a Lean tool for continuous improvement that consists in moving around the company to identify waste and eliminate it. The term Gemba comes from Japanese and literally means “where things happen”.

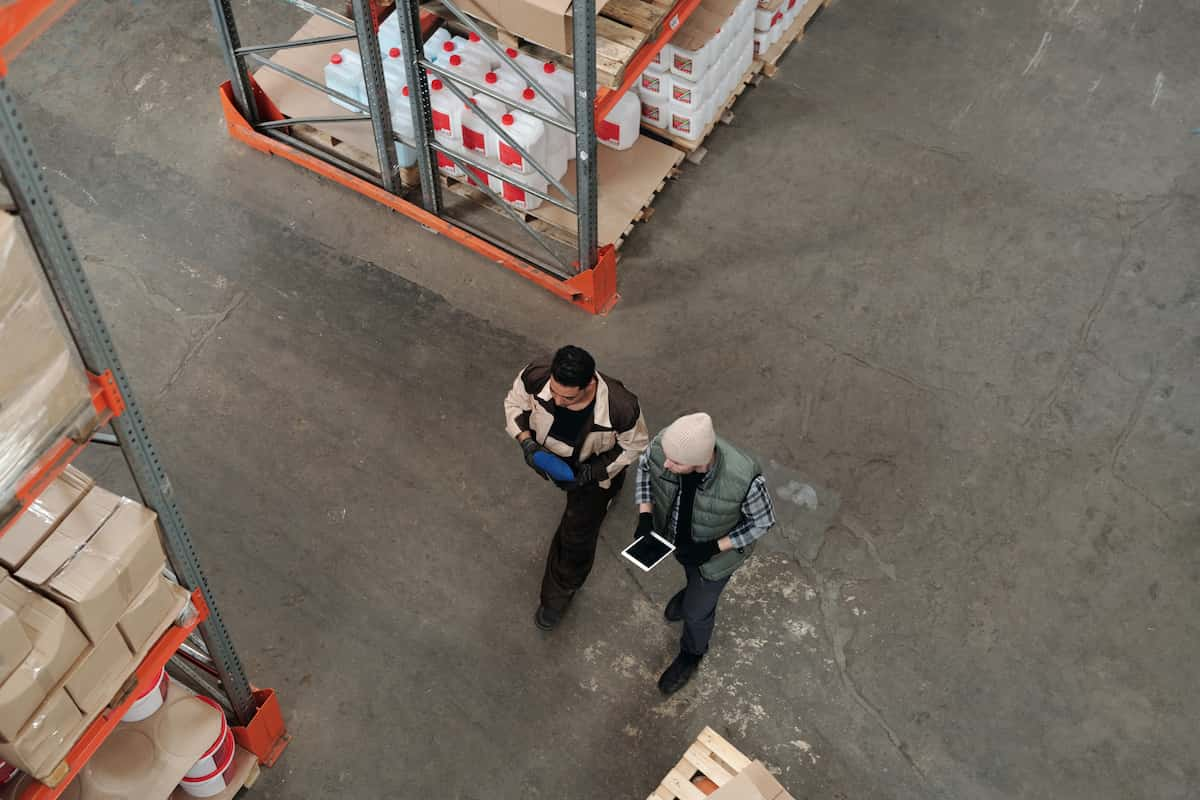

During the Gemba Walk, the head of the company, or another person, goes directly to the field, to the place where the added value is created. Depending on the company, this can be the factory, the workshop or a customer service desk, for example. He then observes with his own eyes the working conditions of the employees, the problems encountered on the spot and the most frequent waste, or Mudas.

After observing the conditions on the spot, the person can ask the employees questions that he has determined in advance. Based on his findings, he can then make decisions to improve processes.

How to conduct a Gemba Walk

To conduct a Gemba Walk, the following methodology can be used:

Listen to what employees have to say about the problems they face.

The conversation can be based on pre-defined questions that can guide the employee. These questions should be open-ended and neutral, so as not to jump to conclusions about the process.

At the end of the article, you will find a list of questions that can be asked during your Gemba Walk.

Discuss with them what can be done to improve the process.

Gemba Walks are often the source of sharing moments between the manager and employees, which usually lead to problem solving.

Help teams work together to solve more complex problems.

Give teams the resources they need to do this, such as time, money and infrastructure.

Necessary preparation

Preparation is essential to the success of the walk. During this preparation, it will be necessary to precisely define the process and the team to be observed, and to delimit the perimeter of action.

Don’t forget to take notes and even, if you think it is relevant, to take pictures.

A relevant and sustainable Gemba Walk

Some points of vigilance must be taken into account to ensure the quality of the process.

For an optimal Gemba Walk, the employees must feel listened to and respected, not judged. Their comments must be received with attention and without judgment, in a benevolent environment.

In a Lean approach, which includes all employees in the search for solutions, each employee can be asked to suggest ways to improve the problems they encounter. They are in the best position to solve the problems that concern their specialties.

For these benefits to be sustainable, it is essential to analyze the findings of the Gemba Walk in order to provide relevant solutions to the problems encountered by the employees.

It is also important to define the optimal duration and frequency of the Gemba Walk to really get into the employees’ daily lives.

Benefits of Gemba Walk

If the Gemba Walk, also called field visit, allows to identify operational problems, it also allows to take a step back on the activity, to detect deviations from the fundamental rules and to detect good practices to be kept. It is therefore a relevant tool to achieve operational excellence in your company.

List of questions to ask during a Gemba Walk :

What exactly are you working on?

Do you encounter frequent problems in your daily work?

Do you have an idea to solve this problem?

What is the task you have the most trouble doing?

Are you satisfied with the organization of your workstation?

What improvements do you think would simplify the process?

We hope that this article and its questions will be useful to you as you complete your Gemba Walk.

Written by Emma Guignard