Model your operations

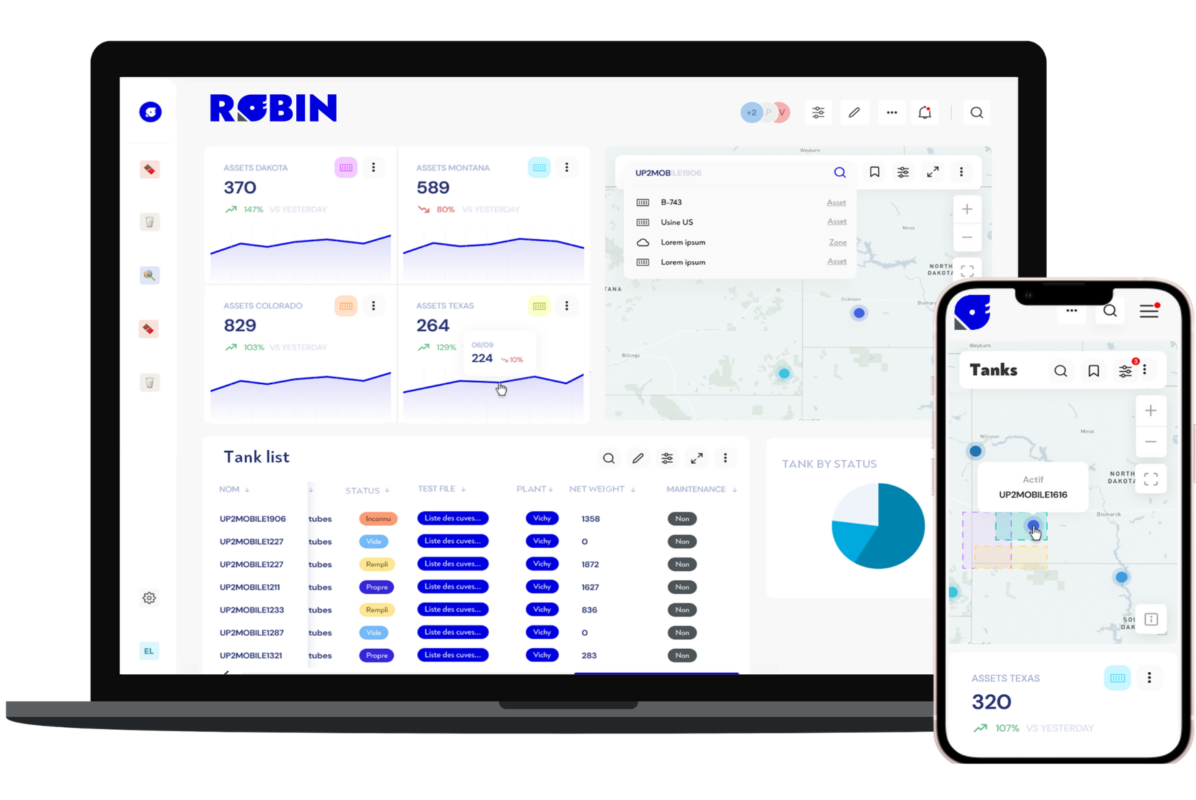

With ROBIN Digital Twin, take advantage of the main features of our software: digital twin, dynamic mapping, and digital simulation of your flows for a 360° view of your production.

7 years of expertise

7 years of expertise

+1200 users

+1200 users

+100 countries coverage

+100 countries coverage

Optimize your production performances with ROBIN, your smart tracking and daily scheduling real-time solution for the manufacturing experts.

ROBIN is more than just a software: it’s your ally in transforming your production processes.

Designed for the field, ROBIN:

Finally, with ROBIN, you aggregate data from your existing information systems (ERP, MES, WMS, forms, barcode scans, spreadsheets…) and create a single source of truth to generate actionable data that effectively improves your processes.

With ROBIN Digital Twin, take advantage of the main features of our software: digital twin, dynamic mapping, and digital simulation of your flows for a 360° view of your production.

With ROBIN Smart Tracking, monitoring and traceability of your work-in-progress is assured. Save more than 30 minutes per day per operator in searching for assets, both within the factory and while in transit at your subcontractors or off-site.

With ROBIN Workflow Control, manage your alerts and optimize your production through real-time access to geolocation data of your assets, their status, and their complete history.

With ROBIN Daily Scheduling, schedule your production in real-time. Gain independence from your ERP and carry out your load-capacity analysis with information updated in real time.

With ROBIN IoT, call on Zozio to offer you a range of industrial sensors selected by use case from our technological partners and adapted to your constraints and your factories.

Use IoT Hub Platform to manually configure the control of your connected objects and industrial sensors, and define ever more precise rules.

Discover our support’s management (project manager, customer success management and technical support) after the purchase of your ROBIN solution and your geolocation solution.

ROBIN: Real-Time Operator’s Business Intelligence Nexus

Beyond its “scientific” name, ROBIN, which means “robin” in English, was named to emphasize the idea of a companion that assists the industrial operator in his daily tasks.

Operators, production managers, methods managers, industrialization managers, Industry 4.0 managers, IT managers, innovation managers, purchasing managers… all benefit from it.

Zozio is also the name of the company founded in 2018 by Bastien Triclot. Bastien is a graduate engineer from Arts & Métiers and the Karlsruher Institut Für Technologie.

The .io refers to the digital environment and connectivity, and the word zozio or “zoziau” in French is a reference to the company founder’s northern origins.

It’s not uncommon to see our ROBIN solution compared with pre-existing tools in their plant information systems (MES, WMS, VMS, ERP, Power BI and other visual management solutions, spreadsheets and industrial planning tools).

ROBIN is not a WMS, MES, ERP, CMMS solution, visual management tool or planning software.

ROBIN is a collaborative, connected industrial logistics traceability management app for operators, production managers and method & Industry 4.0 managers, enabling real-time visualization of work-in-process to avoid overproduction, waste and just-in-time planning.

The data fed into our ROBIN industrial software is high value-added data. It enables in-depth analyses that pave the way for process optimization and savings in terms of time, resources and materials.

It’s a powerful solution, adapted to the high level of competitiveness of large-scale industries that experience several annual peak periods and saturation episodes. It facilitates decision-making thanks to the indispensable analysis of sources of inefficiency in your operations, and contributes through its modernity to the attractiveness of talent.

Thanks to our solution :

Zozio is developing ROBIN, a subscription-based SaaS (software-as-a-service) digital platform dedicated to manufacturing and production manufacturers – in the cosmetics, aeronautics, automotive, chemical, glass and medical device manufacturing (MedTech) sectors.

ROBIN is currently available in three languages (French, English, German) and on all types of screen (TV, computer, smartphone, tablet).

The data collected is formatted using various modules and KPIs (graphs, diagrams, lists, monitoring tables, etc.).

With our geolocation solution, you get indoor precision to 50 cm, and outdoor precision to 10 meters. Our solution is available in 150 countries. The battery life of your IoT is estimated at 5 years, depending on use, and the infrastructure is unwired.

We are tech-agnostic and work with you to define the type of technology best suited to your needs, based on the latest innovations:

To benefit from flexible references and technologies, we are multi-suppliers.

Discover our catalog of integrated sensors for indoor and outdoor geolocation.

To obtain pricing information for our Robin solution, please contact our sales team.

3 ways to do this:

The average commitment period for our service is 36 months, but we remain flexible depending on your specific use case needs.

Guided by Our Industry 4.0 Experts, you’ll benefit from a demonstration tailored to your specific use case. Take advantage of this opportunity to ask all the questions you may have (deployment time, type of IoT provided, pricing) before taking your factory to the next level.