To find out more about our sensors and their specifications, discover all the technologies deployed by Zozio in our catalog of integrated sensors.

[ Interview 4.0 ] George Elias, Zozio : "Most ERPs aren't enough to manage intermediate status"

George Elias is Technical Sales Manager for France and Sales Manager North America dedicated to Zozio’s development in the United States. We interviewed him to share his views on the processes that, when digitized, enable experts in cosmetics production to achieve top performance.

Zozio: George, can you share with us the main difficulties you see – particularly in processes – when you’re in the pre-sales phase with experts in cosmetics production?

George Elias: I think that the most frequent problems are manual operations that could be automated to save time. From the smallest factories to international leaders, I still find a lot of “do-it-yourself” processes.

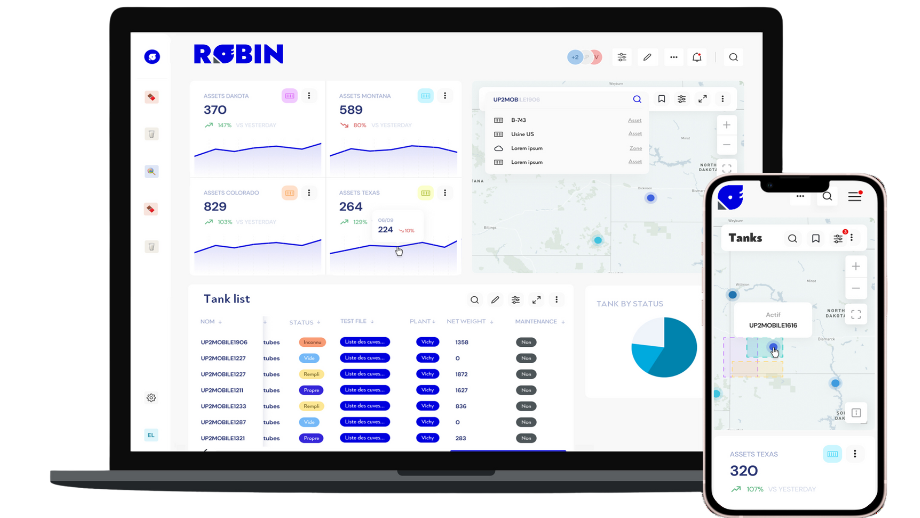

When it comes to recording washing cycles, for example, it’s important for operators to be alerted in real time when a tank has been disinfected, to avoid having to repeat the process a few days later. We set up notifications via computer or smartphone on our ROBIN platform, right up to the deadline, to avoid any oversights or errors. In plants where digital technology is not yet widely used, it’s common to see data entered on a piece of paper taped directly to the tank, which is then transmitted by e-mail via Excel spreadsheets to other teams. With paper, there’s a high risk of these documents being lost or damaged.

Field staff may also find it difficult to distinguish between the status of full and near-empty tanks – which may be indicated as “full” by default, while one contains 100 liters and the other just 10 liters. This kind of nuance is important, and can immobilize tanks that could be used elsewhere, or lead to the unnecessary purchase of tanks to fill in stocks that have been incorrectly entered. In this context, we can see that most ERP systems are inadequate for managing intermediate statuses.

Read also: Manage your cosmetic tanks washing cycles

Using a solution that can record the latest statuses recorded by operators and give teams access to all the information in just a few clicks, in itself removes a daily irritant for production teams. To this, we add ultra-efficient traceability elements thanks to the plant’s digital twin, the mapping of production and storage areas, and the geolocation of work-in-process thanks to IoTs positioned on the tanks, so we know at all times where to find a given type of product, with what status.

Find out more: Locate your mobile tanks within the plant

Zozio: What is the immediate benefit of deployment?

George: It usually takes processing and planning engineers around 2 to 3 hours to cross-check all the data entered manually in the tables extracted from the ERP to prepare production scheduling and planning. With our solution, inventories are automated, and in just a few clicks we have access to an overview of operations, updated in real time and geolocated with a breakdown by zone.

Zozio: Why can’t ERP handle this kind of information?

George: ERP doesn’t do everything. There’s a permanent discrepancy between what’s actually happening in the field and what’s being recorded by the operators, since the data can’t be updated in real time with all the movements taking place. Operators therefore work in isolation at their workstations, unaware of all the hazards that may have occurred during the various stages of production.

It is difficult to define priorities with the ERP, to know maintenance lead times, intermediate statuses at “full” and “empty”, the comings and goings of subcontractors… Or to know the exact status of dormant stocks and the location of empty and immobilized tanks. Once the information has been extracted from the ERP, it circulates as e-mail attachments between the various departments (quality, maintenance, manufacturing, packaging, etc.), whereas the software should be the “central” point for all exchanges. Without an overall vision, it’s difficult to realign priorities according to actual movements in the plant. And managers aren’t always behind their computer screens analyzing everything they receive.

The strength of the solution we are developing lies in its ability to interconnect with any type of pre-existing information system (WMS, MES, ERP, Excel…) and to offer customers the possibility of autonomously generating their own performance indicators to analyze flows and identify areas for improvement.

Zozio: How do you adapt to the constraints of each industrial environment?

George: With my customers, I ask a series of office questions:

– How many sites need to be equipped? In France, Europe or other countries?

– Are there ATEX constraints? ATEX 1 or 2?

– What are the maximum temperatures to which the tanks in the washing zone are exposed?

– What is the objective in terms of performance optimization?

– What applications need to be addressed?

– What levels of precision are required (to choose the most appropriate geolocation technology), etc.?

All the answers I get enable me to draw up specifications, choose the right technologies (UWB, BLE…) that are ATEX-certified… I’ll choose tags that respect all the customer’s precise constraints.

Zozio: How does deployment work?

George: After validating the estimated budget, we draw up a complete specification and present it to the customer. If he agrees, he signs and we prepare a pre-sales meeting with the operational teams where I explain the project and we go through the specifications together. A kick-off meeting is scheduled with the customer prior to deployment. At this meeting, we will discuss the deployment date, on-site constraints, working hours, essential safety equipment… But also the specific equipment that will need to be brought along to install the sensors and anchors, and whether a technician with a ladder is required for installations at height. Staff training requirements are defined, and the full specifications are presented again to remind us what is going to be done.

As for the choice of technologies, since we are tech-agnostic thanks to the support of our partners, we adapt to the project, the budget and the need for customization. For example, we’ve already produced yellow tag boxes for improved visibility!

Talk to us about your project

Zozio: What’s next? How are IoTs and digital projects monitored?

We offer our customers a hardware rental formula, ideal for facilitating IoT maintenance. We use our IoT Hub Platform to monitor IoTs and make sure they’re running smoothly. It lets us know directly when a tag stops communicating, breaks down or runs out of autonomy. Most of our technologies have a battery life of around 3 years, and the infrastructure is cable-free, making them easy to install.

As for the rest, it’s up to our Customer Success Manager to ensure that the whole project runs smoothly for our customer, and to monitor KPIs relating to operational success and performance optimization. If the customer wishes to continue and develop other projects, we open a new specification and off we go again!