What is industrial traceability?

Industrial traceability is the ability to follow all the stages in the life of a product, from its manufacture to its destruction. Traceability thus allows, for a given product, the identification of :

- The origin of its raw materials,

- The places where the product and its components were stored,

- All the stages of the product in the production flow,

- All controls carried out on the product and its components,

- All equipment used during production,

- All customers who consumed the product.

In addition, traceability can be defined at different levels :

- Upstream traceability, which refers to the identification of suppliers and raw materials relating to this product;

- Internal traceability, which refers to the tracking of the product in the production flow, between the reception of raw materials and the finished product;

- Downstream traceability, which refers to the identification of customers.

Logistics traceability and product traceability

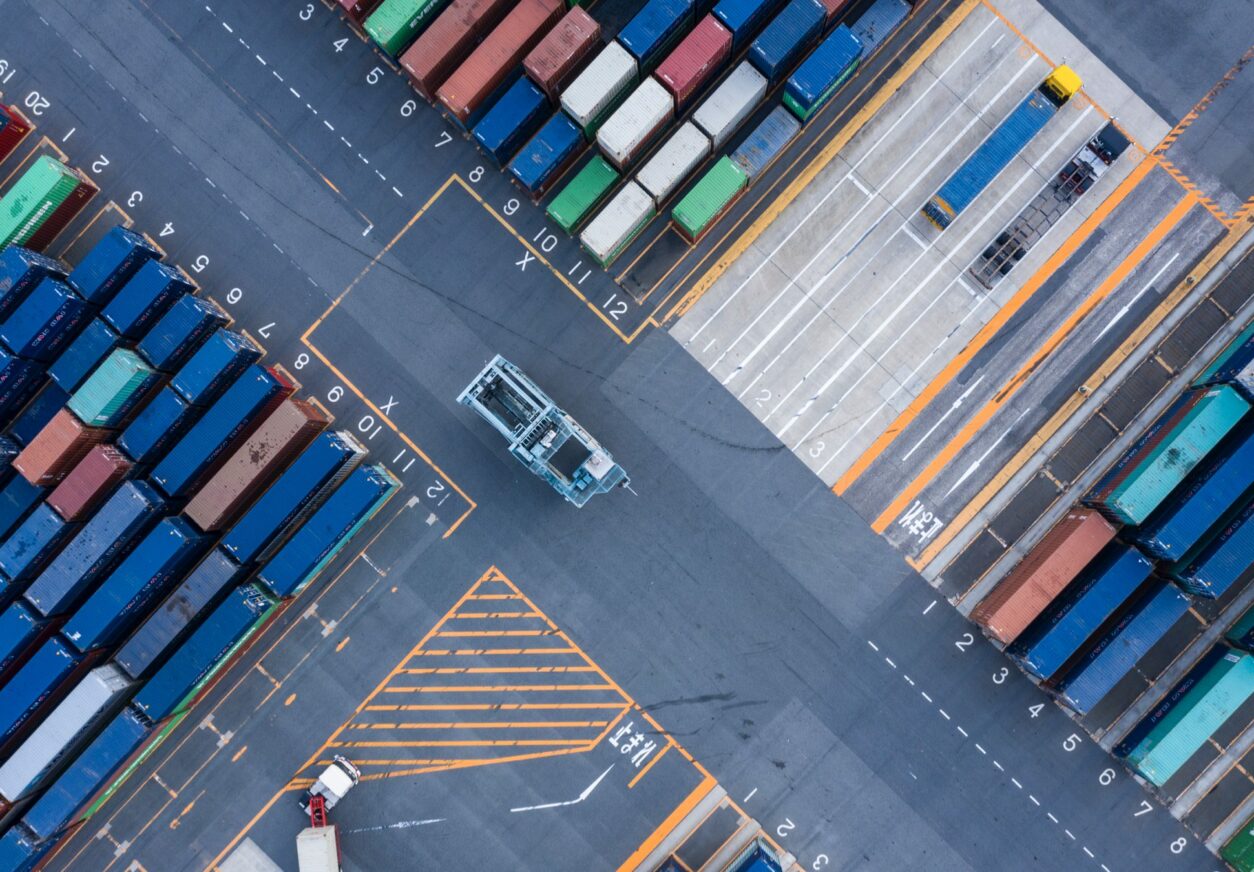

In addition to these different scales, industrial traceability refers to two complementary types of traceability: logistical traceability, also called tracking, and product traceability, also called tracing.

Logistical traceability :

Logistical traceability allows a product to be followed at a quantitative level. Its main objectives therefore concern the monitoring of orders and stocks, the receipt of goods and the location of equipment.

The location of equipment is particularly essential for the performance of companies, as it eliminates the time spent searching for equipment. Among the solutions on the market, Zozio offers a “full Track and Trace” service that allows to follow the movements of equipment throughout the factory.

Product traceability :

Contrary to logistic traceability, product traceability allows to follow a product at the qualitative level. It therefore consists of controlling the quality of products and identifying the causes of a quality problem.

To ensure this type of traceability, companies can use a barcode or radio identification system. To alert employees as soon as a product is suspected, there are also other solutions. Electronic document management (EDM), proposed by Zozio, is a relevant solution because it allows real-time monitoring of product quality.

What are the challenges of industrial traceability?

Traceability plays an essential role in the industrial process. It allows the monitoring and assessment of the quality of products. It thus makes it possible to ensure an optimal quality approach and the safety of the consumers.

One of the challenges of industrial traceability also concerns compliance with regulations. The ISO (International Organization for Standardization) specifies the importance of clearly indicating the unit of identification of the product concerned and of recording the information necessary for traceability upstream and downstream of the product.

To facilitate compliance with these regulations, it is possible to digitise the management of hygiene, expiry, maturation or maceration statuses with the solutions proposed by Zozio.

An example of technology for traceability: the digital twin

Recently, new technologies have appeared on the market and contribute to the optimisation of traceability. One of these is the digital twin.

The concept of a digital twin refers to a simulation tool. It is a virtual clone of a physical system or process. The purpose of the digital twin is to represent in real time the behaviour of the system it copies.

In practice, IoT (Internet of Things) sensors are placed in the field and provide real-time traceability information on the object under study. The digital twin is therefore constantly fed with concrete data.

The digital twin concept allows for increased traceability of a system and can therefore significantly improve the performance of a company.

This concept can be used in the case of predictive maintenance and sizing of workstations, improving the performance of the object under study, reducing the development time of new products, etc.

Ever more efficient technologies

Technologies for traceability, as shown in the previous example, are constantly evolving.

Today, we regularly hear about artificial intelligence, augmented reality or RFID. The traceability solutions now make it possible to go very far in the type of information to be traced. However, companies are looking to implement new value-added services that complement their offer. This is why it is always interesting to find out about new technologies for optimal industrial traceability.

Written by Emma Guignard